- Mail Us

- info@alaskapuf.com

- Call Us

- +91-814-143-3999

Fire-Safe PUF/PIR Panels for All Applications

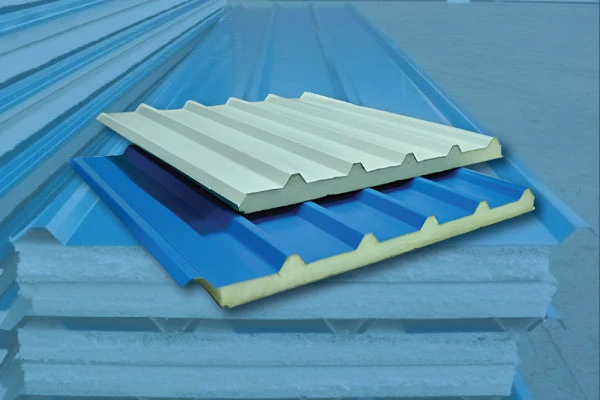

Alaska PUF Industries is a leading manufacturer of PUF/PIR in India. When it comes to insulation materials used in various industries, PUF (Polyurethane Foam) and PIR (Polyisocyanurate Foam) have become popular choices due to their excellent thermal insulation properties, energy efficiency, and versatility. From construction to refrigeration, and from chemical processing to automotive applications, PUF and PIR are used in diverse settings. However, one of the most important concerns when selecting insulation materials is their flammability. Safety is a top priority for any industry, and understanding the fire safety characteristics of PUF/PIR is essential for making informed decisions.

In this, we will explore whether PUF and PIR are flammable, what makes them combustible, and how their fire safety features can be enhanced. We will also look at the applications where these materials are commonly used, the potential fire hazards, and the ways in which PUF/PIR products can meet fire-resistant standards. Whether you are a manufacturer, architect, contractor, or end-user, this detailed guide will provide you with the critical information needed to safely use PUF/PIR materials.

Understanding PUF and PIR

Before discussing the flammability of PUF and PIR, it is essential to understand what these materials are and how they differ.

What is PUF?

PUF (Polyurethane Foam) is a lightweight, durable insulation material known for its superior thermal performance. It is composed of polymerized materials that create a highly cellular structure, offering excellent thermal resistance. PUF is commonly used in the construction industry, cold storage, transportation, and refrigeration units.

- Thermal Performance: PUF is ideal for maintaining temperature control in buildings, refrigerators, and air-conditioning systems due to its low thermal conductivity.

- Acoustic Insulation: It also helps in soundproofing, making it useful in buildings and rooms requiring noise reduction.

What is PIR?

PIR (Polyisocyanurate Foam) is a modified version of PUF that has a chemical structure designed to improve fire resistance. PIR is also used for insulation, but it offers better thermal stability and superior fire resistance compared to PUF. The isocyanurate structure in PIR makes it more heat-resistant, making it a safer choice for certain high-risk applications.

- Thermal Efficiency: Like PUF, PIR also provides excellent thermal insulation, but its ability to perform at higher temperatures makes it suitable for more extreme conditions.

- Fire Resistance: PIR is often the preferred material in areas where fire safety is a significant concern, such as oil and gas industries, pharmaceutical manufacturing, and chemical processing plants.

Is PUF/PIR Flammable?

The key question for anyone using or considering PUF or PIR as an insulation material is whether these materials are flammable, and how they perform in fire-related conditions. Both PUF and PIR are derived fr-om the same family of materials, but their behavior in the presence of fire differs due to their chemical makeup and modifications.

Flammability of PUF

In its pure, untreated form, PUF is flammable. Polyurethane foam, by its nature, is combustible and will catch fire if exposed to an open flame or high temperatures. The cellular structure of PUF, while excellent for insulating, also contains a high amount of air, which can accelerate the spread of fire.

- Flammability Concerns: If exposed to fire, PUF can catch fire rapidly and emit toxic gases, including carbon monoxide, which can make the situation even more hazardous.

- Fire Retardant Treatments: However, PUF can be treated with fire retardants during the manufacturing process. These chemicals are designed to reduce the flammability of PUF, making it less likely to ignite when exposed to flames. The treatment slows the combustion process and helps the material resist heat.

- Conclusion: PUF in its untreated form is flammable. However, fire-retardant PUF can reduce the risks and is widely used in applications where fire safety is important.

Flammability of PIR

Unlike PUF, PIR is designed to be less flammable. The chemical structure of PIR includes an isocyanurate ring that provides improved thermal stability and resistance to combustion. This modification makes PIR a more fire-resistant material than PUF.

- Fire Resistance: PIR has a higher fire-resistance rating and tends to burn more slowly when exposed to flames. Unlike PUF, PIR does not produce as much smoke, and it creates a charred layer that helps protect the underlying material from further damage.

- Performance in High-Temperature Conditions: PIR can withstand higher temperatures without breaking down, making it suitable for more demanding industrial applications, including those with a higher risk of fire hazards.

- Conclusion: PIR is far less flammable than PUF due to its chemical composition. While not entirely fireproof, PIR offers better performance in fire-prone environments and provides enhanced safety over untreated PUF.

Fire Safety Features of PUF/PIR

The fire safety of both PUF and PIR can be significantly improved through various treatments and design modifications. Let’s look at how manufacturers and industries can enhance the fire resistance of these materials.

- Fire Retardant Additives: Both PUF and PIR can be treated with fire retardants. These chemicals can be added during the production process to modify the chemical structure of the foam, slowing down its rate of combustion and reducing its flammability.

- Use of Fire-Resistant Facings: For both PUF and PIR panels, applying a fire-resistant facing material such as aluminum foil, fiberglass, or steel can further improve safety. These facings act as barriers, helping to prevent fire from directly reaching the foam material and slowing down the spread of flames.

- Proper Installation and Maintenance: To maintain fire safety, it is crucial that PUF and PIR panels are installed correctly. Gaps and seams in the panels must be sealed properly to prevent the spread of flames through the insulation.

Applications of PUF/PIR and Their Fire Safety

PUF and PIR are used across various industries, including:

- Construction: Both PUF and PIR are used in buildings to insulate walls, roofs, and floors. These materials are crucial for maintaining energy efficiency and comfort. Fire-resistant PUF and PIR are particularly important in high-rise buildings, where fire safety is a major concern.

- Cold Storage and Refrigeration: Insulation is vital in cold storage facilities to maintain low temperatures. PUF and PIR are commonly used here due to their thermal efficiency. In such environments, fire-resistant versions are necessary to prevent fire hazards from spreading through the stored products.

- Industrial Applications: PIR is frequently used in industries such as oil and gas, chemical, and pharmaceutical where fire safety is critical. The enhanced fire resistance of PIR makes it the material of choice in these high-risk sectors.

Conclusion

Both PUF and PIR have varying degrees of flammability. PUF is flammable in its untreated form, while PIR is far less flammable due to its improved chemical structure. Both materials can be treated with fire retardants and additional fireproofing measures to make them safer for use in fire-sensitive applications. PUF can be made safer with fire-resistant treatments, but PIR is generally the preferred choice for environments where fire safety is a top priority. When choosing PUF/PIR for your insulation needs, it is essential to understand the fire safety standards required for your industry and ensure that the materials used meet those standards. Alaska PUF Industries offers a wide range of fire-resistant PUF/PIR panels that are treated with advanced fire retardants to minimize flammability and provide excellent thermal insulation.

For more information on the flammability of PUF/PIR, call us at +91 8141433999 or email us at info@alaskapuf.com. Our team is here to help you explore our high-quality products and find the right solution for your needs.

Get A Callback

Fill these details & get a callback from Experts

Scan the QR to call